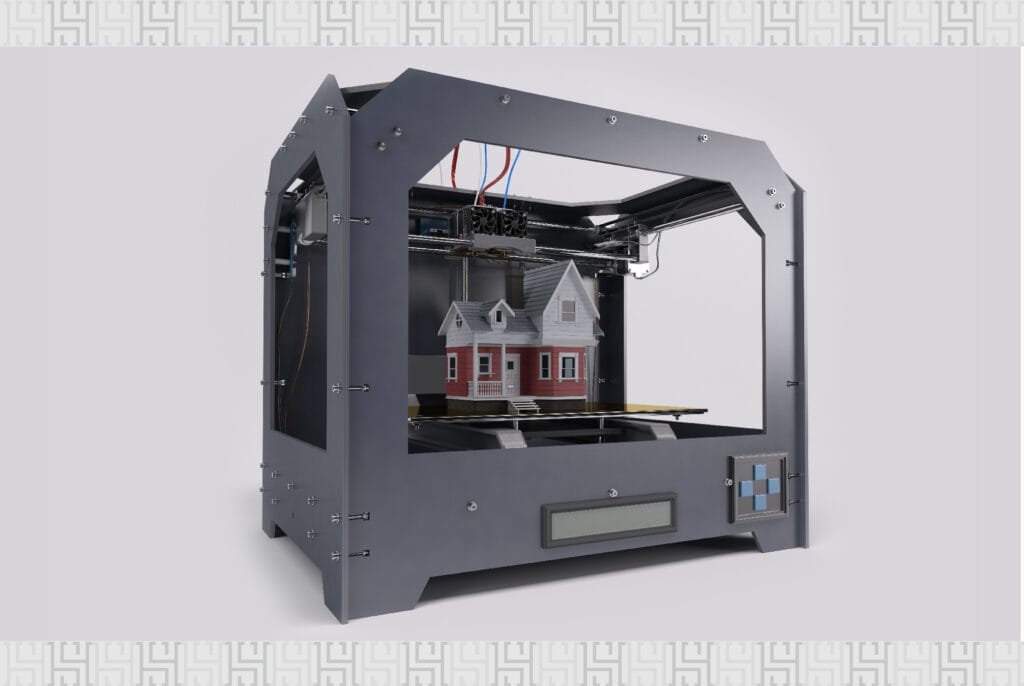

What is 3D Printing in Construction?

3D printing, also known as additive manufacturing, isn’t just a futuristic concept anymore; it is a game-changing technology poised to revolutionize the construction industry. It is about constructing buildings and architectural marvels directly from digital blueprints, layer by layer, with unprecedented design flexibility and efficiency.

Unlike the ink-on-paper process we’re familiar with, this innovative approach uses specialized 3D printers to extrude construction materials layer upon layer, building structures from the ground up. This additive process allows for on-site and off-site construction, opening up many possibilities.

Using 3D printing in construction is on the cusp of explosive growth. As this technology matures and becomes more accessible, construction companies need to understand its processes, applications, and immense potential. Let’s take a deeper look at the 3D printing technology and learn more about its usage in construction and its benefits.

Types of 3D Printers

Just like traditional printers come in different shapes and sizes, 3D construction printers offer a variety of approaches to building. Two primary systems are leading the charge: Gantry Systems and Robotic Arms.

Gantry Systems

The gantry system represents the earliest form of 3D printing in construction, and it’s still a powerful technique. This contour crafting method allows for the creation of large-scale structures with smooth, consistent surface finishes. Essentially, the gantry system builds 3D objects by meticulously stacking 2D layers from the ground up, providing a stable and reliable platform for additive construction.

Robotic Arms

Robotic arms offer a compelling alternative for projects demanding greater flexibility and the ability to create complex geometries. These automatically controlled printers boast a remarkable freedom of movement, allowing them to tackle multiple tasks and print from various angles. A robotic arm equipped with a printer nozzle mounted on a rotating head can extrude material with incredible precision, creating curves, intricate details, and large components that wouldn’t fit within the confines of a gantry system. This adaptability makes robotic arm extrusion well-suited for adding elements to existing structures, working with unconventional designs, and handling materials like cement.

How 3D Printing Technology Works?

3D printing in construction transforms digital designs into tangible structures by meticulously layering construction materials. It is a fascinating process that combines cutting-edge technology with traditional building principles. Here’s a breakdown of the typical steps involved:

1- Digital Design

Every 3D-printed structure begins with a digital blueprint. Architects, engineers, and designers use sophisticated Computer-Aided Design (CAD) software to create detailed 3D models of the building or component. These digital plans specify every dimension, shape, and parameter, laying the groundwork for the construction process.

2- Material Preparation

Once the digital design is finalized, the construction-grade materials are prepared for printing. These are not typical office printer inks but specialized materials like concrete mixes, advanced polymer composites, or metal alloys. These materials are often custom-formulated to meet specific project requirements, ensuring structural integrity, durability, and other critical performance characteristics.

3- Printing Setup

With the design and materials in place, the 3D printer is prepared for action. This could involve setting up a large-scale gantry system at the construction site or positioning a robotic arm in a controlled manufacturing environment according to the project’s scale and complexity. The printing equipment is calibrated and configured to ensure precise material deposition.

4- The Printing Process

The 3D printing process starts with the printer precisely depositing the construction material layer by layer, following the instructions encoded in the digital model. Extrusion nozzles, deposition heads, or other specialized mechanisms carefully control the placement and distribution of the material, building the structure from the ground up.

5- Layer-by-Layer Construction

The printer continues its work, layer upon layer, gradually bringing the digital design to life. Each layer seamlessly bonds to the previous one, creating a cohesive and continuous structure. It is a process that demands precision and control, but the results are often breathtaking.

6- Monitoring and Quality Control

Throughout the printing process, sophisticated monitoring systems and sensors keep a watchful eye on the construction. These systems ensure accuracy, detect potential defects, and maintain consistent quality. Real-time feedback allows for adjustments to be made on the fly, optimizing the printing process and guaranteeing the structural integrity of the final product.

Benefits of 3D Printing in the Construction Industry

3D printing in the construction industry offers many benefits, including:

Time Savings

Traditional construction methods often involve lengthy timelines, with large projects frequently exceeding initial budgets and schedules. However, 3D printing offers a dramatic improvement, potentially slashing project completion times by up to 70%. This accelerated pace empowers contractors to take on more projects, increasing revenue streams and boosting efficiency.

Cost-Effectiveness and Sustainability

3D printing promotes resource efficiency by enabling the precise use of materials. This precision can lead to up to 60% less waste generated on the job site, minimizing material costs and environmental impact. Furthermore, using the necessary materials eliminates surplus purchases and reduces storage expenses. These combined cost and time savings translate to a significant increase in profitability for construction companies.

Enhanced Safety

One of the most significant advantages of 3D printing in construction is its positive impact on worker safety. Training employees to operate 3D printers makes construction tasks easier, reducing the risk of on-site injuries. This technology fosters a safer work environment for everyone involved.

Design Flexibility

Last-minute design changes are no longer a source of stress and delays. 3D printing allows for design customizations right up until the printing process begins. This flexibility eliminates the headaches and costly rework associated with traditional construction methods, empowering architects and designers to explore new creative possibilities without fear of significant project disruptions.

The construction industry is embracing 3D printing at an accelerating pace, and this trend is only set to explode in the coming years. To stay competitive and capitalize on this transformative technology, you need to understand how to integrate 3D printing into your operations. Mastering these tools is key to unlocking significant gains in efficiency and productivity without sacrificing quality. Ready to explore more about 3D printing in construction? Contact HS Group‘s today at +967 2 237793/4/5 or info@hs-gp.com.